The Advantages of Composite Toe Neoprene Boots A Comprehensive Guide

The Advantages of Composite Toe Neoprene Boots A Comprehensive Guide

Ankle rain boots are designed to provide waterproof protection while offering a comfortable and stylish option for rainy weather. These boots typically feature a shorter shaft that reaches just above the ankle, providing flexibility and ease of movement. They are ideal for urban environments, outdoor walks, and light hiking in wet conditions.

One of the key points to consider is the type of socks you plan to wear with your rubber boots. If you're an outdoor enthusiast who typically wears thicker socks for warmth and cushioning, you should account for this when selecting your size. Failing to do so can lead to a tight fit, which can be uncomfortable during extended wear. The best practice is to try on the boots with the socks you intend to use.

Another essential feature of composite toe neoprene boots is their electrical hazard protection. Many models are designed to meet stringent ASTM (American Society for Testing and Materials) standards, allowing them to protect wearers from electrical shocks while working in environments where such hazards are present.

Durability and Protection

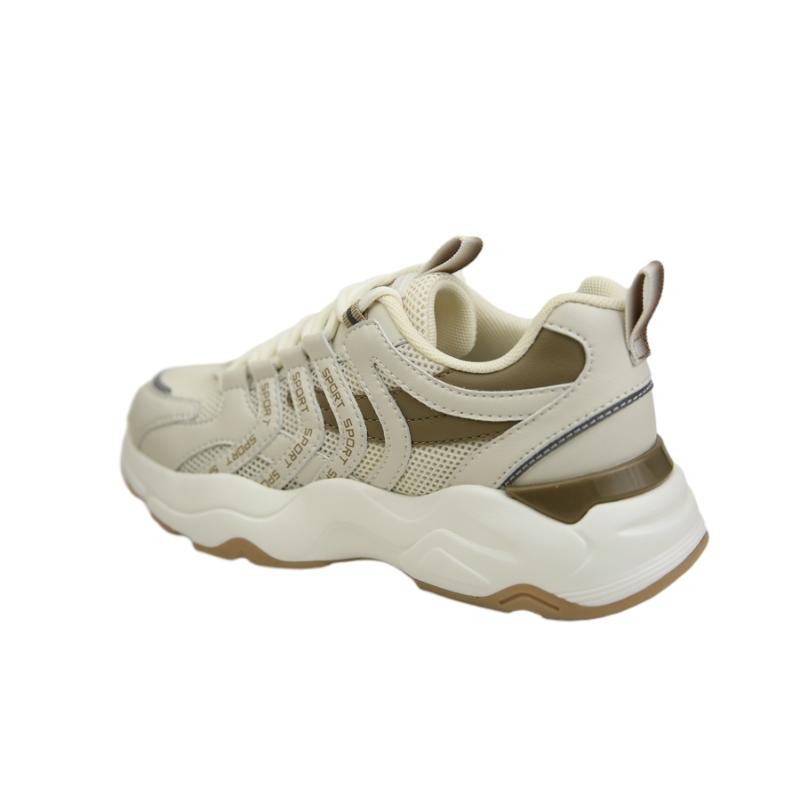

sports sneakers for women. Modern sports sneakers for women provide excellent support, shock absorption, and traction, suitable for activities like running, hiking, or even yoga. They also incorporate breathable materials to keep feet cool and dry during intense workouts, preventing blisters and other foot issues.

sports sneakers for women. Modern sports sneakers for women provide excellent support, shock absorption, and traction, suitable for activities like running, hiking, or even yoga. They also incorporate breathable materials to keep feet cool and dry during intense workouts, preventing blisters and other foot issues.When choosing fishing boots, you may want to consider more comfort and lightness. Some manufacturers specifically design breathable, lightweight fishing boots to ensure comfort during extended fishing sessions. Brands like Cabela's, Simms, and Hodgman offer a variety of styles and affordable options to suit different fishing needs.

Fishing boat deck boots are tailored for the specific demands of fishing on boats, offering features such as non-marking soles, waterproofing, and quick-drying materials. These boots provide anglers with the necessary grip and protection while moving around the deck, ensuring a secure footing and comfort during fishing activities on boats.

Comfort is another essential factor, particularly for anglers who spend long hours on the water. Many spike fishing boots come equipped with cushioned insoles and ergonomic designs that support the feet and provide the necessary arch support. This comfort reduces fatigue, allowing anglers to focus on their fishing rather than on sore feet. Some models also offer breathability, which helps keep the feet cool during warmer days.

Enhancing Safety on the Water

The breathable canvas upper also ensures that your feet stay cool and dry, reducing the risk of blisters and other foot irritations The breathable canvas upper also ensures that your feet stay cool and dry, reducing the risk of blisters and other foot irritations

The breathable canvas upper also ensures that your feet stay cool and dry, reducing the risk of blisters and other foot irritations The breathable canvas upper also ensures that your feet stay cool and dry, reducing the risk of blisters and other foot irritations canvas hunting boots.

canvas hunting boots.Fishing boots with waterproof features are essential for anglers seeking reliable protection and comfort during fishing expeditions. These boots are designed to offer waterproofing, traction, and support, ensuring that anglers can navigate through wet and challenging environments with confidence. The waterproof construction provides anglers with the necessary features for a successful and comfortable fishing experience.

Deck boots for fishing are designed to provide anglers with reliable traction, durability, and protection while on deck. These boots are crafted to withstand exposure to water, offering waterproofing and slip-resistant soles to ensure stability and safety on wet surfaces. Deck boots are essential for anglers working on boats, providing comfort and support during fishing expeditions.

Why Choose the Right Waders?

1. Encouraging Water Consumption Automatic cat fountains utilize flowing water to attract cats. The gentle sound and movement of water can entice even the most reluctant drinkers to hydrate more frequently. This increased water intake can help mitigate the risk of urinary issues and contribute to better kidney health.

The introduction of automatic ink dispensers has revolutionized the printing industry, offering multiple benefits, including enhanced precision, waste reduction, and increased efficiency. As the technology continues to advance, these dispensers will play an even more critical role in meeting the demands of modern printing environments. Businesses that invest in this technology will not only improve their operational efficiency but also gain a competitive edge in an ever-evolving market. Embracing automatic ink dispensers is not just a trend; it is a strategic move towards a more efficient and sustainable future in printing.

Choosing the Right Extractor

The Importance of Portable Welding Fume Extractors in Modern Welding Practices

Lastly, the size and portability of the unit should align with the workspace layout. A compact design may be ideal for smaller areas, while larger models might be suitable for bigger factories or workshops.

Beyond their mechanical prowess, automatic paint dispensers have also fostered trust within environmental spheres due to their sustainable practices. Many modern models are designed to minimize waste, utilizing nearly all of their ingredients with little overflow or spillage. This zero-waste philosophy not only benefits the environment but also offers a cost-effective solution for businesses by maximizing the usage of raw materials.

2. Electronics Manufacturing In soldering processes, flux fumes can be toxic to health. By using portable fume collectors, companies can minimize inhalation risks for technicians, ensuring a safer workspace.

Investing in a high-quality welding fume extractor is not just an expense; it's a crucial step toward ensuring the wellbeing of your workforce. With our affordable options, you can enhance your workplace safety without breaking the bank.

When paired with automated welding arms, wall mounted fume extractors provide consistent airflow and filtration across the workspace. The result is a high-performance welding environment where the automation process can run smoothly without any interruptions caused by environmental hazards. A proper fume extraction system is essential to achieving both high productivity and a clean, safe work environment.

2. Sustainability Focus With growing awareness of environmental issues, automatic ink dispensers will likely incorporate greener technologies. Innovations may include the use of eco-friendly inks and more energy-efficient designs to appeal to environmentally conscious consumers and businesses.

Sustainability

1. Precision and Consistency One of the standout features of robotic welding arms is their ability to perform tasks with a level of precision unattainable by human welders. The robotic systems can execute complex welding patterns uniformly, reducing the likelihood of defects and ensuring consistent quality across multiple pieces.

- Manufacturing Used for transporting raw materials and finished products within production facilities.

Advantages of Steel Floor Systems

In today's fast-paced logistics industry, flexibility is essential. That’s why Yeed Tech Co., Ltd. offers a portable shipping container lift that allows you to easily move lifting capabilities wherever they're needed. Lightweight yet sturdy, this portable solution is perfect for on-the-go operations, enabling you to tackle container handling tasks wherever they arise.

The incorporation of H-beam cutting machines into manufacturing processes significantly impacts construction efficiency. By improving the speed and accuracy of beam cutting, these machines enable builders to assemble projects more quickly and with greater confidence in the structural integrity of their materials. As a result, construction timelines can be shortened, allowing for faster project completion and reduced labor costs.

One key aspect that underscores the experience of using an automatic spray coating machine is its unparalleled efficiency. Unlike manual spraying, where consistency is often a challenge, the automatic variant ensures a uniform layer of coating, regardless of the complexity or texture of the surface. For instance, in the automotive industry, these machines apply paint coatings with exceptional precision, reducing material waste and minimizing human error. Users have reported that automated systems save substantial time compared to manual labor, thereby increasing production flow and profitability.

At Yeed Tech Co., Ltd., we understand the demands of modern shipping logistics. Our shipping container lifting equipment is engineered for both performance and durability, ensuring that you can handle containers of all sizes with ease. With precision engineering and cutting-edge technology, our products provide unmatched lifting capabilities, reducing the time and labor costs associated with container handling.

Expertise in materials science enhances the effectiveness of these systems. Understanding the chemical composition of coatings and their interaction with substrates is crucial. For industries like electronics, where precision is paramount, automated systems offer superior control over film thickness and surface coverage, avoiding common issues such as orange peel or sagging.

The construction industry has witnessed a significant transformation over the years, particularly with the increasing adoption of advanced materials and systems that enhance structural integrity, reduce labor costs, and improve overall efficiency. Among these innovations, the steel floor system stands out as a critical element in modern building construction. This article explores what steel floor systems are, their advantages, applications, and future trends in the construction sector.

When metals are fused together through welding, high temperatures vaporize the metal, generating fumes that are often hazardous to human health. Common materials involved in welding, such as mild steel, stainless steel, and aluminum, release various toxic substances, including manganese, lead, and chromium. Prolonged exposure to these fumes can result in conditions such as “metal fume fever,” chronic bronchitis, reduced lung function, and even more severe illnesses like cancer.

A stacking bar is a metal beam or bar used to secure and stabilize maritime containers when they are stacked on top of one another during shipping or storage. These bars help distribute weight evenly across the containers, reducing the risk of tipping or toppling and ensuring that the entire stack can withstand various stresses, including environmental factors such as wind and vibration during transport.

What is a Wall-Mounted Welding Exhaust Fan?

As the construction industry faces increasing scrutiny over its environmental impact, the use of tower steel has also evolved to become more sustainable. Steel is one of the most recycled materials globally, with a recycling rate of around 90%. This makes it an excellent choice for environmentally conscious builders. By repurposing scrap steel, construction companies can significantly reduce their carbon footprint while also cutting down on production costs.

The portrayal of strength is not limited to physical endurance; it infers emotional and mental fortitude. In the socioeconomic landscape of the Philippines, many families face challenges that require not only physical labor but also a deep-seated determination to overcome obstacles. The image of “sasakyang nagbubuhat ng lalagyan” thus inspires us to reflect on our own burdens. What figurative containers are we carrying? Are they filled with responsibilities related to family, work, or personal aspirations?

As the construction industry continues to evolve, several trends are emerging regarding steel floor systems. Advances in technology, such as Building Information Modeling (BIM), are facilitating more efficient design and collaboration among stakeholders. Additionally, the increasing focus on sustainability is driving innovations in steel production processes, aiming to reduce carbon footprints and increase recycling rates. Furthermore, the integration of smart technologies into steel floor systems, such as monitoring sensors, is expected to enhance safety and maintenance, ensuring that buildings meet the demands of modern urban living.

Portable Fume Collector An Essential Tool for Modern Workspaces

The Importance of Container Handlers in Modern Logistics

Trustworthiness of a vendor or product is often validated by certifications and feedback from real-world applications. For instance, choosing equipment that meets ISO 9001 certifications provides assurance of quality management systems, pointing to a product's reliability and the manufacturer’s commitment to meeting customer needs. Case studies and testimonials from existing users offer invaluable insights into the equipment's performance, providing potential buyers with the confidence that their investment will yield the expected benefits.

The future of welding is undoubtedly evolving, and with technologies such as welding arms and integrated fume ventilation systems, businesses can look forward to a more efficient, safer, and cleaner working environment, driving the industry forward into the next era of advanced fabrication.

The Future of Container Transportation Control

In summary, forklift containers (contenedor de carretilla elevadora) play a pivotal role in enhancing the operational capabilities of forklifts across multiple industries. By understanding the significance, design considerations, and advantages of these containers, businesses can optimize their material handling processes. As industries continue to demand greater efficiency and safety, the evolution of forklift containers will undoubtedly remain at the forefront of logistical advancements, facilitating smoother operations and improved productivity. Investing in suitable forklift containers can ultimately lead to a leaner, more efficient supply chain, which is essential for competitiveness in today’s market.

3. Design Flexibility Steel floor systems offer architects and engineers a high degree of design flexibility. The ability to span large distances without the need for intermediate supports opens up possibilities for innovative layouts and open floor designs. This is especially crucial in modern office buildings and shopping complexes.

The primary strength of automated spray coating systems lies in their ability to deliver consistent results while optimizing resource use. Unlike traditional methods, these systems are designed to apply coatings with precision accuracy, reducing wastage significantly. This level of precision is achieved through advanced sensors and computerized controls that ensure each application meets stringent quality standards. As a result, companies not only save on materials but also achieve a higher quality finish that can withstand the demands of various environments.

Automatic spray painting machines are engineered to deliver consistent and high-quality finishes, which are crucial in industries such as automotive, furniture, and electronics. Their ability to maintain a uniform coat of paint over various surfaces sets them apart from manual application methods. This uniformity not only enhances aesthetic appeal but also extends the longevity and durability of the coated material.

In industries where automated welding arms are used, effective local exhaust ventilation for welding is crucial in ensuring both safety and productivity. Local exhaust ventilation systems capture and remove fumes directly from the source, ensuring that harmful particles do not contaminate the air around the welding operator. These systems are particularly important in larger fabrication shops, where multiple welding stations are often operating simultaneously.

Conclusion

In conclusion, container lifting devices are integral to the functionality of modern logistics. Their role in improving efficiency, safety, and sustainability cannot be overstated. As the industry continues to evolve, embracing technological advancements and sustainability practices will define the future of container handling. The ongoing development of innovative lifting solutions ensures that businesses are well-equipped to meet the increasing demands of global trade, reinforcing the importance of these devices in supporting economic growth and international commerce.

7. Market Demand and Economic Conditions Current market trends and economic conditions also influence prices. When demand for container lifting machines rises, prices may increase due to competition for limited units. Conversely, economic downturns may lead to lower prices as manufacturers and dealers strive to move inventory.

- Data Collection and Analysis Many robotic welding systems come equipped with advanced sensors and data collection capabilities. This allows manufacturers to monitor performance in real time, identify inefficiencies, and make data-driven decisions to optimize their processes continually.